According to the IEA (International Energy Agency) global hydrogen demand in 2030 could exceed 200 million tons per year to meet agreed upon Net Zero emission targets. The greatest challenges in meeting projected demand, however, remain the growth of hydrogen production capacity (currently limited primarily to electrolysis), and the availability of a safe and cost-effective hydrogen storage and transport infrastructure. Such infrastructure must be robust enough to transport and deliver large amounts of hydrogen and such safe delivery must be at a competitive price.

Turning waste into clean hydrogen

H2-Enterprises’ waste-to-hydrogen technology has the ability to convert non-recyclable plastics and other organic wastes into CO2-emission-free, clean hydrogen, which can be offered at competitive prices. CO2 produced as a by-product of the conversion process can, moreover, be captured and made available for commercialization. Critically, hydrogen so produced can be safely stored and transported in liquid organic hydrogen carrier (LOHC) and that hydrogen can be used locally or exported. Clean hydrogen, so produced, can be used as a fuel or an industrial feedstock with applications ranging from industrial and transportation applications to power generation.

H2-Enterprises’ technological solutions eliminate environmental pollution while creating CO2-emission-free energy. In so doing, such technologies will help close the gap between clean hydrogen supply and demand, a solution urgently needed and on a large scale – to help substantially decarbonize our planet.

The world needs more hydrogen

Today: Waste on Land

![]()

Tomorrow: Waste to Hydrogen

The world is drowning in waste

Today: Waste in Oceans and Rivers

![]()

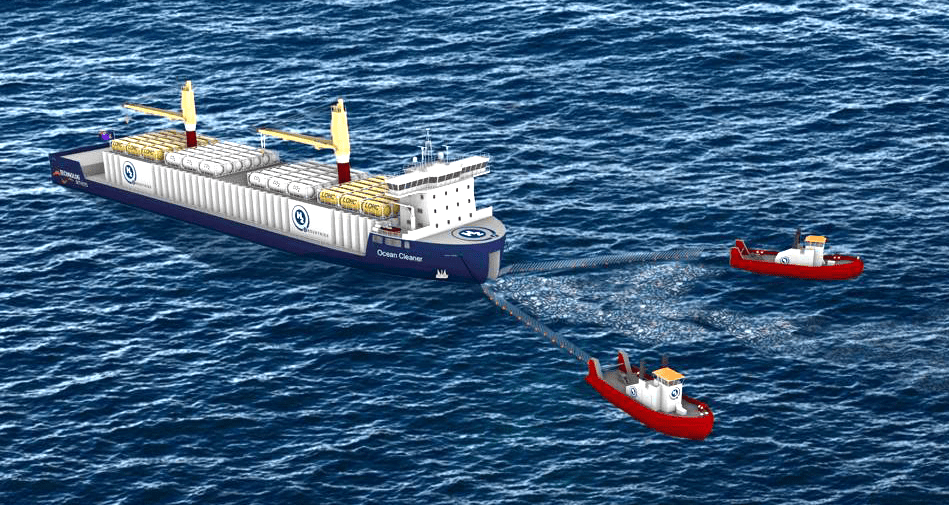

Tomorrow: Ocean Cleaner - Waste to Hydrogen

Waste-to-hydrogen technology

H2-Enterprises’ proprietary waste-to-hydrogen technology transforms organic waste, including plastics, sewage sludge and existing landfill waste, using a high temperature conversion into clean hydrogen. It is not a combustion process. It does not burn waste by adding air or Oxygen and avoids the release of any harmful waste gas.

H2-Enterprises’ technology relies on a process called “thermolysis” which allows the conversion of plastic and other organic waste to hydrogen and CO2 and it does so without burning a match. The process has two-stages, first, steam reforming, followed by a water gas shift reaction and a gas-separation of H2 and CO2. At the end of the process, the target product, hydrogen, is purified, as needed, and CO2 is being captured for commercialization.

The hydrogen produced from the described process can be safely transported and stored in LOHC, as mentioned above. Using these technologies, hydrogen can be sold to domestic or international off-takers and/or further processed into synthetic fuels (eDiesel or Sustainable Aviation Fuel) or used as CO2-emission-free, clean energy for industrial applications.